From SLA to Silicone: Prototyping Methods Explained

Prototyping plays a critical role in product development by helping manufacturers test ideas, validate designs, and reduce costly...

Uncategorized

Over 15 years crafting models for manufacturing teams

We deliver 3D models in just 1–2 days with clear documentation.

Supporting manufacturers with SolidWorksdesigns molding and parts.

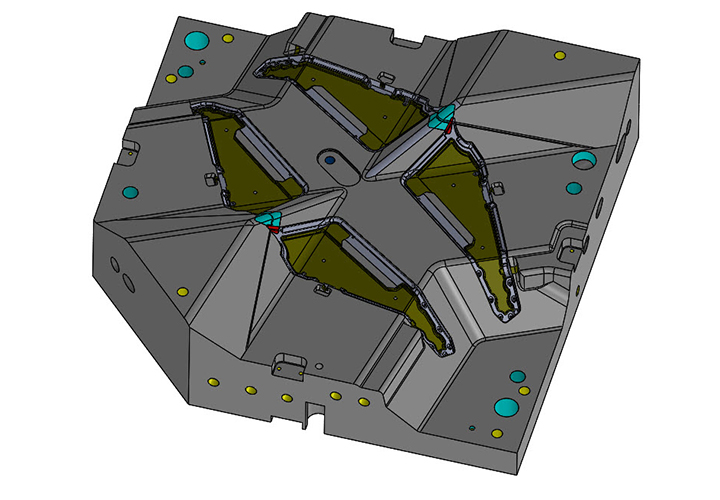

We specialise in creating accurate, production-ready CAD designs for molds, parts, and prototypes. Using SolidWorks, we help manufacturers visualise and refine their ideas before any physical production begins. Our goal is to deliver high-quality design files that are easy to interpret, modify, and move into tooling or prototyping stages. By focusing purely on the design process, we eliminate unnecessary delays and ensure your project starts with a solid foundation. From simple part drawings to complex mold layouts, our work supports faster manufacturing, better communication with tooling teams, and a smoother path to final product development.

Every project begins with a clear conversation to understand your part or mold design needs. From there, we follow a structured workflow that includes concept review, preliminary layout, and precise SolidWorks modeling. Whether working from scratch or refining an existing idea, we ensure every design is built to spec and meets manufacturing requirements. We pride ourselves on fast turnaround — typically delivering initial models within 1–2 days — while maintaining accuracy and flexibility. If 2D drawings or exploded views are needed, we provide those too, helping our clients bridge the gap between design vision and shop-floor readiness.

We are committed to being a trusted design partner for manufacturers who need reliable, fast, and professional CAD work. Our focus is not on mass production, but on providing the foundational design work that drives it. With years of experience in mold and part design, we understand what tooling teams look for and what manufacturing requires. That’s why we create clear, practical designs that reduce back-and-forth and support efficient downstream production. Whether you’re launching a new product or improving an existing one, you can count on us to provide precise, well-documented designs — on time, every time.

We specialise in creating accurate, production-ready CAD designs for molds, parts, and prototypes. Using SolidWorks, we help manufacturers visualise and refine their ideas before any physical production begins. Our goal is to deliver high-quality design files that are easy to interpret, modify, and move into tooling or prototyping stages. By focusing purely on the design process, we eliminate unnecessary delays and ensure your project starts with a solid foundation. From simple part drawings to complex mold layouts, our work supports faster manufacturing, better communication with tooling teams, and a smoother path to final product development.

Every project begins with a clear conversation to understand your part or mold design needs. From there, we follow a structured workflow that includes concept review, preliminary layout, and precise SolidWorks modeling. Whether working from scratch or refining an existing idea, we ensure every design is built to spec and meets manufacturing requirements. We pride ourselves on fast turnaround — typically delivering initial models within 1–2 days — while maintaining accuracy and flexibility. If 2D drawings or exploded views are needed, we provide those too, helping our clients bridge the gap between design vision and shop-floor readiness.

We are committed to being a trusted design partner for manufacturers who need reliable, fast, and professional CAD work. Our focus is not on mass production, but on providing the foundational design work that drives it. With years of experience in mold and part design, we understand what tooling teams look for and what manufacturing requires. That’s why we create clear, practical designs that reduce back-and-forth and support efficient downstream production. Whether you’re launching a new product or improving an existing one, you can count on us to provide precise, well-documented designs — on time, every time.

With over 15 years of hands-on experience, Advance Mold & Part Design has delivered more than 1,200 precision mold designs for 300+ manufacturers across various industries. What began with a single CAD station has grown into a trusted operation known for fast turnarounds, accurate modeling, and flexible solutions. Today, we consistently deliver 3D models in 2 days or less, helping clients reduce lead times and bring products to market faster.

Our vision is to revolutionise the mold design process by combining speed, precision, and innovation. We aim to be the go-to partner for manufacturers seeking reliable, high-quality mold and part design. By delivering quotes in under 4 hours and 3D models in just 2 days, we help businesses scale faster, reduce production delays, and stay competitive in an evolving manufacturing landscape driven by efficiency and smart engineering.

With over 15 years of hands-on experience, Advance Mold & Part Design has delivered more than 1,200 precision mold designs for 300+ manufacturers across various industries. What began with a single CAD station has grown into a trusted operation known for fast turnarounds, accurate modeling, and flexible solutions. Today, we consistently deliver 3D models in 2 days or less, helping clients reduce lead times and bring products to market faster.

Our vision is to revolutionise the mold design process by combining speed, precision, and innovation. We aim to be the go-to partner for manufacturers seeking reliable, high-quality mold and part design. By delivering quotes in under 4 hours and 3D models in just 2 days, we help businesses scale faster, reduce production delays, and stay competitive in an evolving manufacturing landscape driven by efficiency and smart engineering.

Precise, fast, and production-ready design solutions.

Learn more about our design process, turnaround time, file delivery, and how we support your manufacturing team.

We typically deliver initial CAD models within 1–2 business days after the project scope is confirmed.

Yes, we can include 2D drawings for documentation, tooling, and manufacturing reference as needed.

We support manufacturers across automotive, industrial, consumer, and tooling-focused sectors with precise design work.

Prototyping plays a critical role in product development by helping manufacturers test ideas, validate designs, and reduce costly...

UncategorizedIn modern manufacturing, the importance...

UncategorizedWhether you need part, mold, or prototype designs, we’re here to support your next manufacturing step efficiently

Interested in working with us?

jschwabe@advancemolddesign.com

42 Mamnoun Street, Saba Carpet and Antiques Store, UK

The point of using Lorem Ipsum is that it has more-or-less normal